Innovative & Creative

Since its inception in 1988, Radiant Technologies, Inc. has been dedicated to innovating characterization equipment for non-volatile memory technologies, non-linear electromechanical materials, MEMS, and actuator/sensors. Radiant pioneered and developed the first ferroelectric test system which quickly became the world-wide industry standard for characterizing non-linear materials. Precision and accuracy has been the driving force behind the engineering of our test equipment and thin ferroelectric film components. Radiant designs its testers to minimize distortion and maximize accuracy.

Radiant offers a wide range of Precision Non-Linear Test Systems (PiezoMEMS Analyzer, Multiferroic II, Premier II, LCII and RT66C) for material research, development and device qualification. Precision Test Systems vary by Frequency, Sample Area and Voltage (see Precision Tester Comparison Chart Below).

Vision Data Management Software drives Radiant's test systems. Vision Software allows researchers the simplicity, power and flexibility to take experiments to the next level. Vision offers 155 Tasks in Total. Vision is the only software package available for ferroelectric testers that provides exceptional freedom to design, conduct and review all procedures associated with any material experiment. Vision Software dramatically increases the productivity of the researcher, reducing the time required to acquire data in an experiment. Vision’s enhanced productivity directly reduces cost of test. Vision dramatically increases the complexity of the research that may be accomplished by allowing researchers to combine different measurement tasks with environmental controls into an automated test procedure managed by programmable logic embedded with automated data collection, analysis and plotting tools.

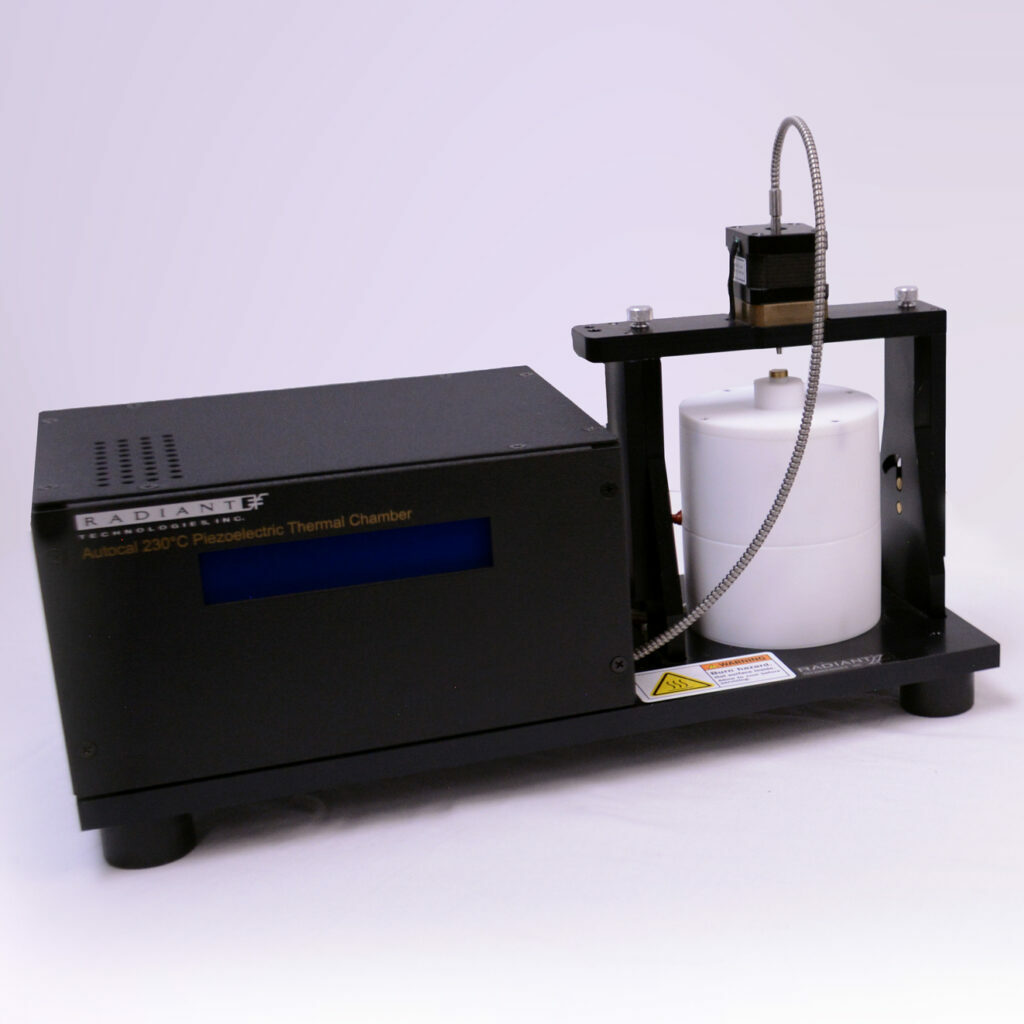

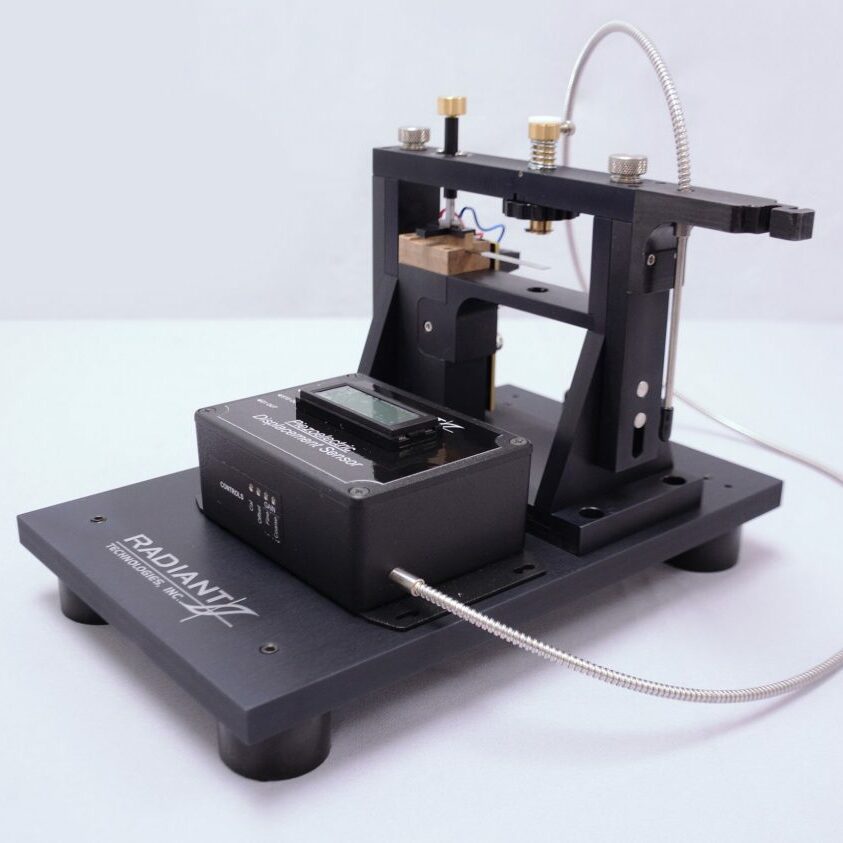

Complete accessory packages for High Voltage Testing to 10kV, Thermal Testing, Piezoelectric, Magnetoelectric, Transistor and Reliability Testing are provided for each Precision Ferroelectric/Multiferroic Test System.

Precise Measurements You Can Trust

See our full range of Precision Testers and find out why Radiant is the world leader in ferroelectric testing

Over 30 years of Experience

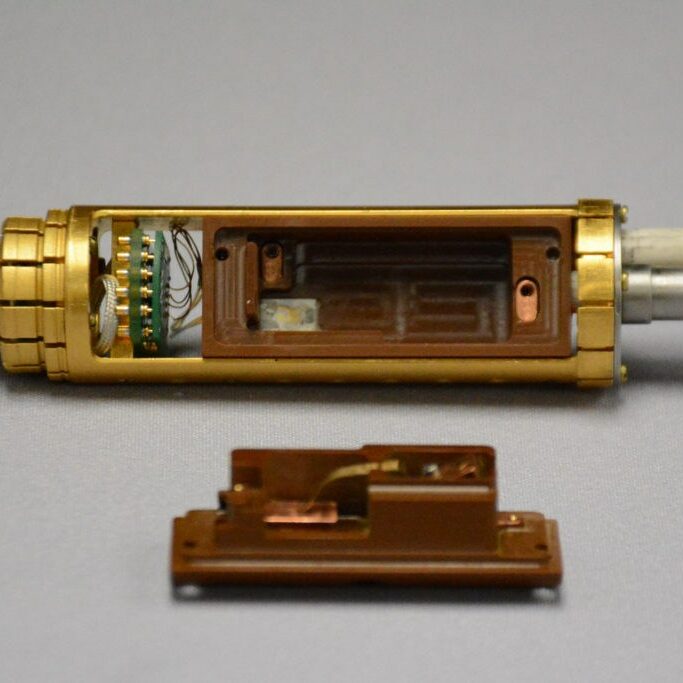

Since 1988, Radiant Technologies, Inc. has established the worldwide standards for electrical evaluation of ferroelectric materials of all types. Radiant continues to sell the most sophisticated test equipment for these materials and their applications. Ferroelectric are one of the foundations of modern society. They are found everywhere in everyday life: electronic equipment, cell phones, medical diagnostic instruments, cameras, and military sensors. Radiant makes its own ferroelectric materials and transfers these various functions into integrated circuit scale devices, greatly reducing their cost while greatly increasing their quality and functionality. The key to this strategy is an integrated ferroelectric device manufacturing process developed over the last decade that can support product development and sales. Today, Radiant offers this capability as the only integrated ferroelectric device foundry in the United States.

Radiant's advanced ferroelectric technology rests upon three legs:

1) Radiant's unique integrated ferroelectrics manufacturing process,

2) Radiant's position as the premier test equipment company in the world for ferroelectric materials, and

3) Radiant's proprietary model for the physics of ferroelectric devices.

Radiant's test equipment and procedures were created and refined on its ferroelectric process line, making them realistic and practical. In turn, Radiant's thin ferroelectric film process is one of the most advanced in the world from the proper use of Radiant's test equipment in refining film properties and reliability. Both the testers and the process are designed around a powerful physical model of the ferroelectric capacitor, a model that has been tested and proven continually with the testers in the fabrication process.