Accuracy and Uniformity

Radiant offers three different Thin Film Piezoelectric Test Bundles that accurately determine coefficients for piezoelectric thin films. These tools enable the characterization and control of piezoelectric films during product development and manufacturing.

High Resolution Angstrom-Level Measurement Platform

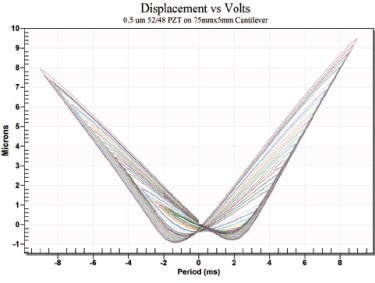

A Laser Vibrometer attached to a Radiant Test System accurately measure the piezoelectric coefficient (d33) of thin piezoelectric films deposited on cantilevers and membranes or clamped to a substrate.

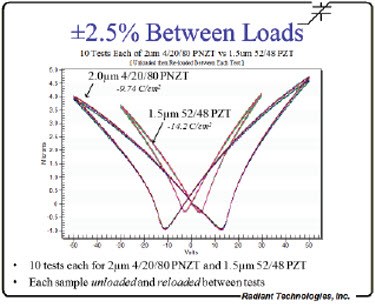

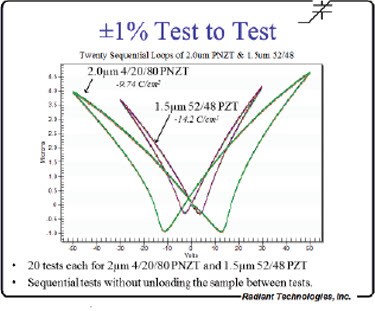

Radiant’s PiezoMEMS Analyzer, Multiferroic II and Precision LCII Testers use 18-bit ADC’s, have 76 microvolt per bit resolution, and exhibit a noise floor of~300µV for a single pass.

A Radiant Test System Combined with a Laser Interferometer can reach 0.2 Ångstrom (0.02nm) resolution in d33 piston motion.

Thermal Chambers can be added to the Thin Film Piezoelectric Test Bundle to measure temperatures from-196C to 600C in a single test profile.

- Laser Vibrometer with a bit resolution of 0.3 Ångstroms and bandwidth of 2 MHz.

- Advanced Piezoelectric Software- Advanced piezoelectric software executes automated tests and provides clean displacement measurements for thin piezoelectric films or piezoelectric MEMs The software can be configured for different measurements and generate multiple plots at the touch of a button. It corrects multiple measurements for test stand drift and then averages/smooths the measurements to correct high and low frequency noise.

- Test Stand for precise measurements.

NanoMeter Measurement Platform

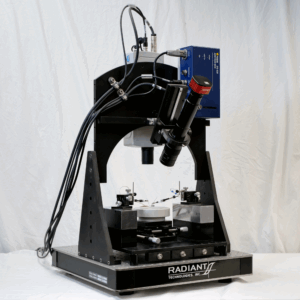

A Radiant Precision Test System combined with a Nanometer Measurement Platform allows accurate measurement of the piezoelectric (d33) coefficient on packaged parts. The cost-effective IVS-500 is mounted horizontally to be used with Radiant’s Simple Test Station, Bulk Ceramic Test Fixture and/or a Thermal Stage (-196C-650C). An auxiliary USB camera is included in the system to allow precise focus onto the target of interest.

Resolution above the noise floor with averaging = ~1 nanometer

- 70-400μm Spot Diameter

- 10kHz band width or 100kHz quoted upon request

- Affordable solution to measure bulk materials & pMEMS devices with large features

- Fully automatic control from the Advanced Piezoelectric Task provided with Radiant’s Test Systems

- For measuring the small displacement motion of clamped thin films, we recommend Radiant’s High-Resolution Angstrom Level Measurement Platform-VibroOne

Dual e31 Piezoelectric Cantilever System

A Radiant Tester combined with the with a Dual e31 Piezoelectric Cantilever System provides a revolutionary approach to measuring both direct and converse e31 coefficients simultaneously using a single sample and test fixture. This technique reduces the need for multiple samples and fixtures, significantly improving efficiency and accuracy in piezoelectric characterization. The Dual e31 system simplifies the process by using two capacitors on a single cantilever to capture both coefficients in one test.

Dual e31 Test Fixture

- Built off our converse e31 measurement system

- Photonic displacement sensor self-calibrates

- Five BNC connections

- Four pogo pins on cantilever frontside

- Fifth for cantilever backside to ground substrate

- Vision controlled connection swapping in final design (Multiplexer)

- Lid (not shown) reduces thermal and electrical noise

Dual e31 Measurement

- Apply voltage to the actuator capacitor to bend the cantilever while measuring the displacement.

- Converse e31 and surface strain

- Simultaneously capture the charge generated by the sense capacitor as it is bent by the actuator capacitor.

- Sense polarization

- Calculate the Direct e31 coefficient by dividing the surface strain into the sense polarization.