Accuracy and Uniformity

Radiant offers two different Thin Film Piezoelectric Test Bundles that accurately determine coefficients for piezoelectric thin films. These tools enable the characterization and control of piezoelectric films during product development and manufacturing.

Thin Film Piezoelectric Test Bundle - VibroOne

A Polytec Laser Vibrometer attached to a Radiant Test System accurately measure the piezoelectric coefficient (d33) of thin piezoelectric films deposited on cantilevers and membranes or clamped to a substrate.

Radiant’s PiezoMEMS Analyzer, Multiferroic II and Precision LCII Testers use 18-bit ADC’s, have 76 microvolt per bit resolution, and exhibit a noise floor of~300µV for a single pass.

A Radiant Test System Combined with a Laser Interferometer can reach 0.2 Ångstrom (0.02nm) resolution in d33 piston motion.

Thermal Chambers can be added to the Thin Film Piezoelectric Test Bundle to measure temperatures from-196C to 600C in a single test profile.

The Thin Film Piezoelectric Test Bundle - VibroOne Includes:

- Polytec Laser Vibrometer with a bit resolution of 0.3 Ångstroms and bandwidth of 2 MHz.

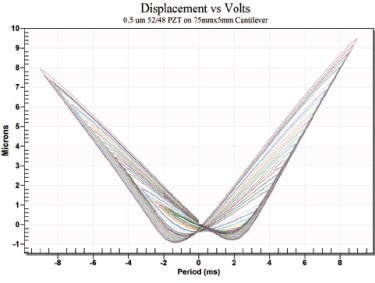

- Advanced Piezoelectric Software- Advanced piezoelectric software executes automated tests and provides clean displacement measurements for thin piezoelectric films or piezoelectric MEMs The software can be configured for different measurements and generate multiple plots at the touch of a button. It corrects multiple measurements for test stand drift and then averages/smooths the measurements to correct high and low frequency noise.

- Test Stand for precise measurements.

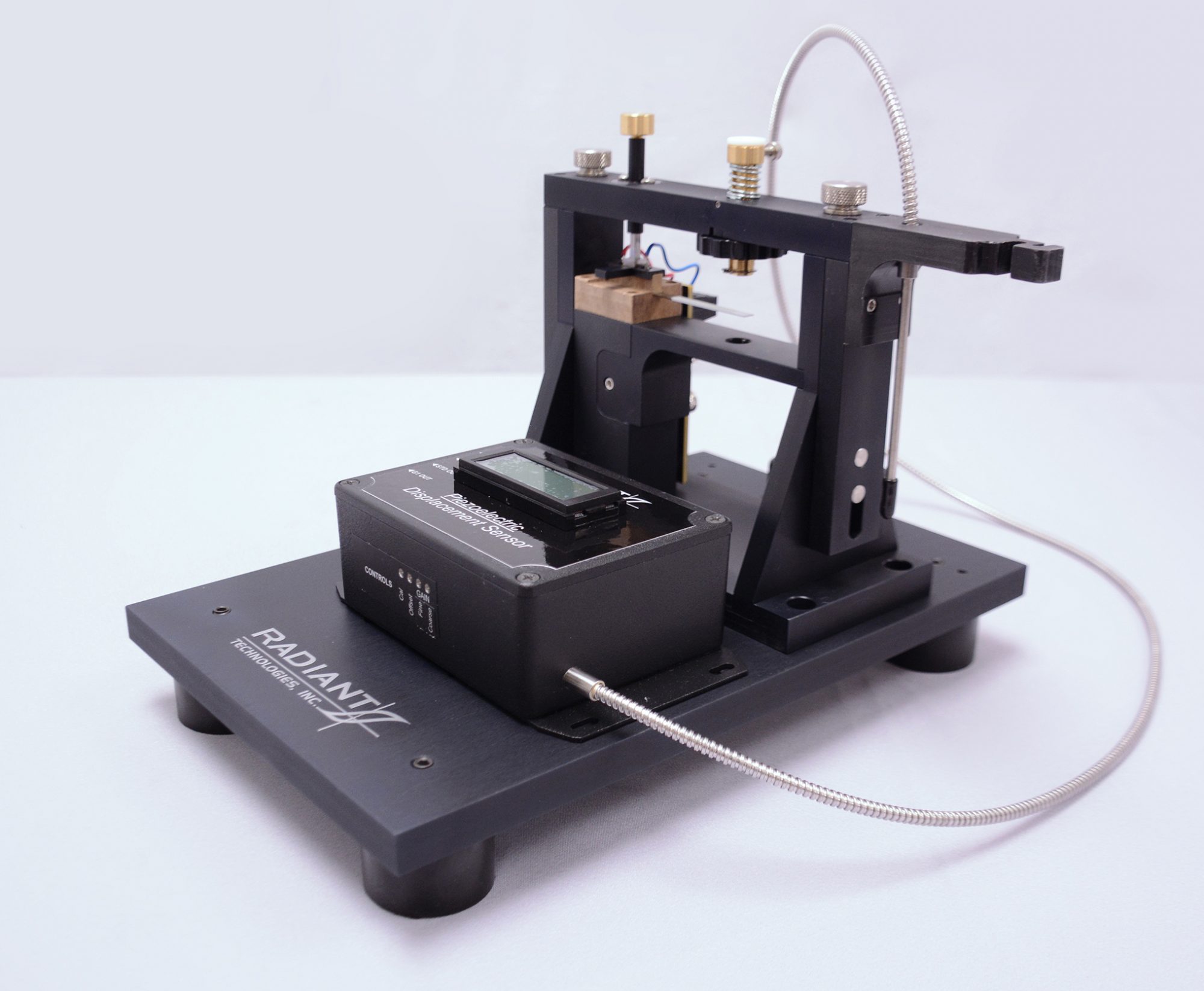

Thin Film Piezoelectric Test Bundle - e31

A Radiant Tester combined with the with Thin film Piezoelectric Test Bundle (e31) measures the piezoelectric coefficients (the e31, d31 and e33) of thin piezoelectric films deposited on cantilevers. Voltages applied to the piezoelectric film bend the substrate in various directions. The displacement is captured by the photonic sensor (built-in to the The Thin film Piezoelectric Test Bundle-e31) which is configured to capture the motion of the cantilever tip.

Photonic sensors generally have minimum spot diameters of 0.3mm to 3mm. Only large flat structures can be measured with a photonic sensor.

The Thin Film Piezoelectric Test Bundle – 31 accomodates the following cantilever sizes.

- With a photonic sensor for 4 Inch/ 72mm cantilevers (4")

- With a photonic sensor for 2 Inch/42mm cantilevers (2")

The Thin Film Piezoelectric Test Bundle - e31 Includes

Piezoelectric Displacement/Phontonic Sensor

1 micron with a range of 6mm. The Piezoelectric Displacement Sensor analog output is calibrated to generate 5 microns/volt (or =0.2V/micron) on the near side slope. When the Piezoelectric Displacement Sensor analog output is connected to a Precision Test System Sensor port that output voltage is measured by an ADC whose resolution is 0.3mV per step.

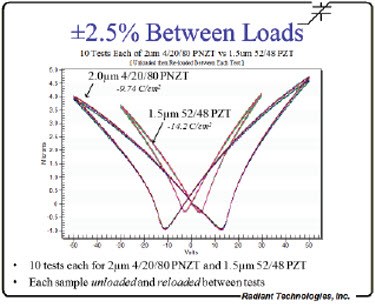

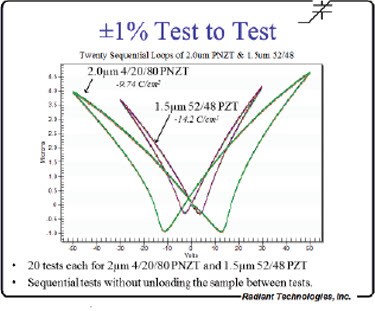

Advanced Piezoelectric Software- Advanced piezoelectric software executes automated tests and provides clean displacement measurements for thin piezoelectric films or piezoelectric MEMs The software can be configured for different measurements and generate multiple plots at the touch of a button. It corrects multiple measurements for test stand drift and then averages/smooths the measurements to correct high and low frequency noise.